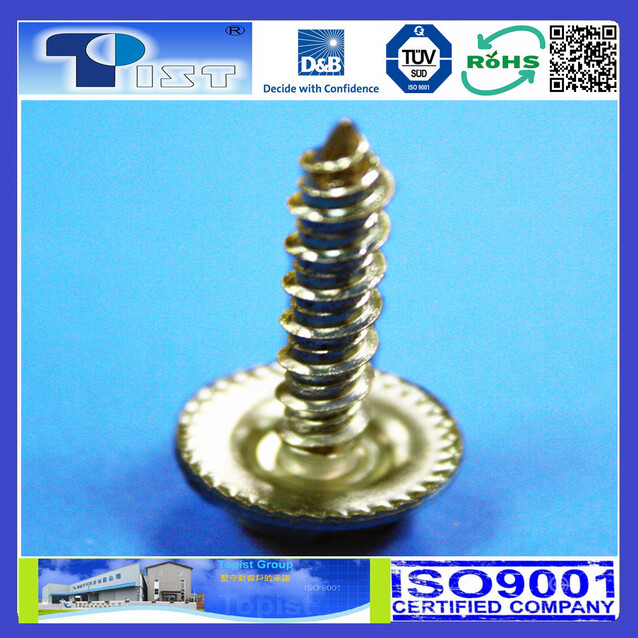

SEMS

SEMS are bolts, which are called bolts with a dodecagon at the end. The main feature of these the screws is they are equipped with corresponding washers, which is convenient to use. The biggest advantage is that can saves time and does not require any manual adjustment of the flat pad, which can make the production line easily, and quickly to improve work efficiency.

The high-strength combination bolts mainly applied on railway, highway bridges, boiler steel structures, industrial plants, high-rise civil buildings, tower mast structures, crane machine and automobile engines.

The steel structure requires high-strength friction-type bolts. It is characterized by a bolt, which is called a dodecagon at the end of the bolt. When installing, a special electric wrench must be used. There are two socket heads on the top and bottom. One is sleeved on the hexagon of the nut and the other is sleeved on the decagon of the outer hexagonal screw. When tightening, apply a clockwise torque to the nut and apply an equal and counterclockwise torque to the dodecagon of the bolt, so that the end of the hexagonal screw and the neck of the dodecagon are subjected to torsion shear to the neck after installation. This torsion-shear type high-strength hexagonal screw is a one-time use screw, generally cannot be removed after installation.

The function of the SEMS is simple, it is connect and fasten the objects, because the elastic flat pads are used to rub the thread on screws, so there is no need to match the elastic flat pads when using. Moreover, when in use, the SEMS has a particularly big effect, which is anti-loosening.

Advantages of SEMS:

1.Pre-assembled parts ensure faster assembly speed.

2.Reduce the failures caused by people, improper assembly or forgot to install the lock washer.

3.It is easy to assemble very small size products.

4.It can be maintained and repaired in hard-to-reach or restricted areas.

5.Reduce commodity numbers, optimize inventory and logistics, and save costs.

6.Remove is faster and easier. Loosing lock washers are difficult to remove, especially from the counterbore.